Self-Tapping Thread Inserts In Steel Stainless And Carbon Steel

Unit: PC

Size:

Price:

Self-Tapping Thread Inserts In Steel Stainless and Carbon steel

Self-tapping thread inserts in steel stainless and carbon steel are screwed into preformed or predrilled holes and cut their own threads into the wall for permanent installation. Eliminates the time and expense of tapping. Provides a strong wear and vibration resistant thread. The steel inserts are hardened with a zinc and clear chromate finish. Stainless are type 303. Can be installed with hand installation tools. Hole size listed is for reference only. Optimum hole size to be determined through experimentation. A 60 degrees countersink is required for flush mounting. For use in aluminum, aluminum alloy, magnesium and mild steel.

It is suitable for installation in the following materials:

- Light alloys

- Cast iron, brass, bronze NF metals

- Plastics, laminates

- Hardwoods

Material & Finish :

-Stainless steel 303, passivated

-Carbon steel, zinc-plated, yellow chromated

Other materials, designs and finishes on request :

-Brass

-Carbon steel, zinc-plated, blue passivated

-Carbon steel, zinc/nickel plated, transparent passivated

Technical Parameters :

Dimensions in mm

| Metric Series | |||||||

| Carbon Steel Part No. | Stainless Steel Part No. | Internal Thread | External Thread | Length | Guideline values for receivinghole diameter | Minimum borehole depthfor blind holes | |

| Carbon steel(1215) | SUS303 | A | E | P | B | L | T |

| 307030001 | 307030002 | M3 | 5 | 0.6 | 4 | 4.7 to 4.8 | 6 |

| 308030001 | 308030002 | M3 | 5 | 0.6 | 6 | 4.7 to 4.8 | 8 |

| 307035001 | 307035002 | M3.5 | 6 | 0.8 | 5 | 5.6 to 5.7 | 7 |

| 308035001 | 308035002 | M3.5 | 6 | 0.8 | 8 | 5.6 to 5.7 | 10 |

| 307040001 | 307040002 | M4 | 6.5 | 0.8 | 6 | 6.1 to 6.2 | 8 |

| 308040001 | 308040002 | M4 | 6.5 | 0.8 | 8 | 6.1 to 6.2 | 10 |

| 307050001 | 307050002 | M5 | 8 | 1 | 7 | 7.6 to 7.7 | 9 |

| 308050001 | 308050002 | M5 | 8 | 1 | 10 | 7.6 to 7.7 | 13 |

| 307060001 | 307060002 | M6 | 10 | 1.25 | 8 | 9.5 to 9.6 | 10 |

| 308060001 | 308060002 | M6 | 10 | 1.25 | 12 | 9.5 to 9.6 | 15 |

| 307080001 | 307080002 | M8 | 12 | 1.5 | 9 | 11.3 to 11.5 | 11 |

| 308080001 | 308080002 | M8 | 12 | 1.5 | 14 | 11.3 to 11.5 | 17 |

| 307100001 | 307100002 | M10 | 14 | 1.5 | 10 | 13.3 to 13.5 | 13 |

| 308100001 | 308100002 | M10 | 14 | 1.5 | 18 | 13.3 to 13.5 | 22 |

| 307120001 | 307120002 | M12 | 16 | 1.75 | 12 | 15.2 to 15.4 | 15 |

| 308120001 | 308120002 | M12 | 16 | 1.75 | 22 | 15.2 to 15.4 | 26 |

| 307140001 | 307140002 | M14 | 18 | 2 | 14 | 17.2 to 17.4 | 17 |

| 308140001 | 308140002 | M14 | 18 | 2 | 24 | 17.2 to 17.4 | 28 |

| 307160001 | 307160002 | M16 | 20 | 2 | 14 | 19.2 to 19.4 | 17 |

| 308160001 | 308160002 | M16 | 20 | 2 | 24 | 19.2 to 19.4 | 28 |

| 307180001 | 307180002 | M18 | 22 | 2 | 18 | 21.2 to 21.4 | 21 |

| 308180001 | 308180002 | M18 | 22 | 2 | 24 | 21.2 to 21.4 | 28 |

| 308200001 | 308200002 | M20 | 26 | 2 | 27 | 25.2 to 25.4 | 31 |

| 308220001 | 308220002 | M22 | 26 | 2 | 30 | 25.2 to 25.4 | 34 |

| 308240001 | 308240002 | M24 | 30 | 2 | 30 | 29.2 to 29.4 | 34 |

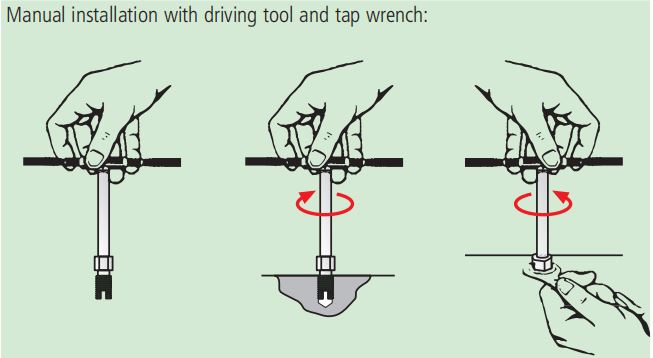

Manual installation:

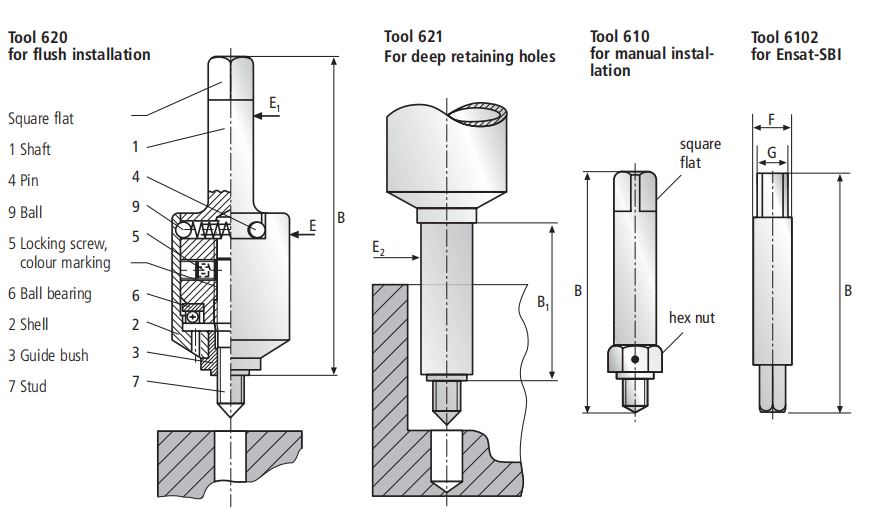

Manual driving takes place using the driving tools 620, 621 or 610 and a tap wrench:

1. Drill the hole: see page 6 for the correct diameter, countersink if necessary.

2. Screw the Ensat onto the driving tool with the cutting slot or cutting bore pointing downwards.

3.Drive in the Ensat until appr. 0.1 -0.2 mm below the surface of the workpiece. When using tool 620 and 621,the rotatable shell must rest against the externally visible stop pins in such a way that it is driven round clock- wise by the pins.

Draving tools:

FQA

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer since 2004 in Shen zhen ,China .

Q2: Do you have stock for items ?

A2: Yes , most of items are in stock for shippment .

Q3: How long is your delivery time?

A3: Generally it is 1day for stock item,10-15 days for custom items or big quantity over 50000 pcs .

Q4: Can you provide samples ? is it free or extra ?

A4: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q5. What about the payment terms?

A5: Generally 100% T/T in advance before shippment or mass production ,and we can also consult according to your requirement.

Q6: What's your advantage?

A6: The competitive prices, fast delivery and high quality. responsible-oriented employees strict tolerance, smooth finish and long- life performance.

Q7: What are your machining equipment?A7: CNC milling machines, CNC turning machines, stamping machines,grinding machines,automatic lathe machines, tapping machines, grinding machines,screw machines, cutting machines and so on.

Q8: How to guarantee the Quality of Industrial Parts?

A8: We have been in fastener field over 19 years with full experience. And there are 5 checks in the whole processing, We have IQC (incoming quality control), IPQCS (in process quality control section), FQC (final quality control) and OQC (out-going quality control) to control each process of industrial parts production.

Hot Tags: self-tapping thread inserts in steel stainless and carbon steel, suppliers China, manufacturers, factory, buy, in stock, made in China